Our Machines.

The process of designing with waste materials is simple. Your resources are everywhere and all you need are the right tools to get started!

The injection process.

1 Design

2 Collect

3 Shred

4 Inject

5 Sell

We have a varied selection of shredders to help prep your plastic for the injection process. Whether you’re happy to use some elbow grease to keep costs low, or are looking for something motorised and speedy for efficiency, we’ve got you covered.

All our shredders have been carefully designed to ensure they are easy to assemble and use, but we also offer resources and online support should you need it.

Please don’t hesitate to get in touch should you have any questions or queries.

Shredders.

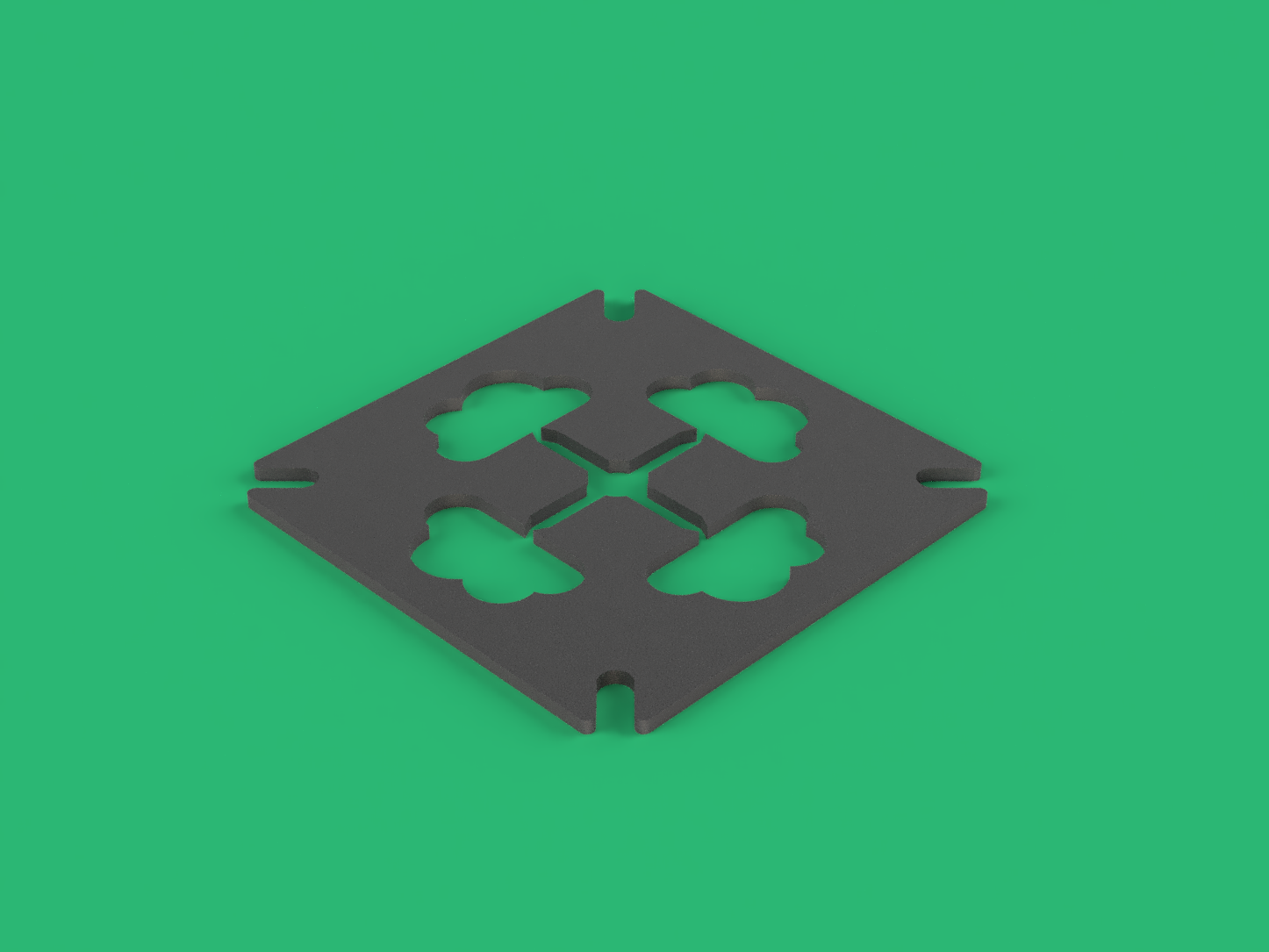

Once you have prepped and shredded your plastic, it’s ready to be injected into your chosen mould, using an injection machine.

The Injection Machine applies heat and pressure to melt your recycled plastic into the mould of your choice. With a 150cm³ melting volume, it is probably one of the largest, yet most affordable injection machines out there.

Our machines support a wide range of thermoplastics, including PLA, PETG, HDPE, ABS, PS, PP, and LDPE. They are compact in size, making them easily portable.

Take a look at our selection below, or click the ‘Get in touch’ button to discuss your ideas, questions or potential order.

Injection Machines.

Our machines are designed with education in mind. That means that they are simple to assemble and disassemble, they are easy to repair and modify and those with no previous experience can be taught how to use them.

An Injection machine is used to melt the plastic and insert it into a mould.

We also provide consultancy.

Got an initial idea for a recycling project?

We can help you get from waste to product with the expert knowledge and advice of an experienced sustainable designer.