Plastics: Different Types

A complete guide on the different types of plastic and how best to use them with the Sustainable Design Studio’s Injection Machines.

Plastics are synthetic materials primarily derived from petroleum and consist of hydrocarbons — chains of hydrogen and carbon atoms. Most plastics are polymers, which are long molecules composed of repeated units of a simpler molecule known as a monomer. This structure contributes to the durability and longevity of plastics.

Due to their low cost, ease of manufacture, and versatility, plastics are used in a wide and growing range of products, from shampoo bottles to spacecraft. The ubiquity and vast volume of plastic production are causing significant environmental damage due to their slow decomposition rate; recent studies suggest plastics can take up to 500 years to decompose because of their strong molecular bonds. Consequently, all the plastics ever used by previous generations are still present today and will continue to impact the planet for centuries to come.

Most plastics also contain additives — either organic or inorganic compounds that enhance performance or reduce production costs. The quantity and type of additives vary widely depending on the plastic's intended use.

Plastics are found globally, often accumulating in unwanted locations.

What Are Plastics?

Different Types of Plastic

-

Thermoset

Thermosetting plastics are composed of polymers that form cross-links to establish permanent bonds, rendering them incapable of being remelted—once shaped, they remain in that form indefinitely. A helpful analogy is to compare thermosetting plastics to bread; just as bread simply burns when reheated instead of returning to its doughy state, thermoset plastics cannot revert to their original form. As a result, these types of plastics are not recyclable. Common products made from thermoset plastics include panhandles, toilet seats, shoe soles, and tyres.

-

Thermoplastics

Thermoplastics are a type of plastic polymer that soften upon heating and harden when cooled. These materials can undergo multiple cycles of heating and cooling: they melt into a liquid when heated and solidify upon cooling. Thermoplastics are akin to butter, which can melt and reset repeatedly. Examples of items made from thermoplastics include garden chairs, buckets, single-use cutlery, and bottles.

Simply put we can only easily recycle Thermoplastics!

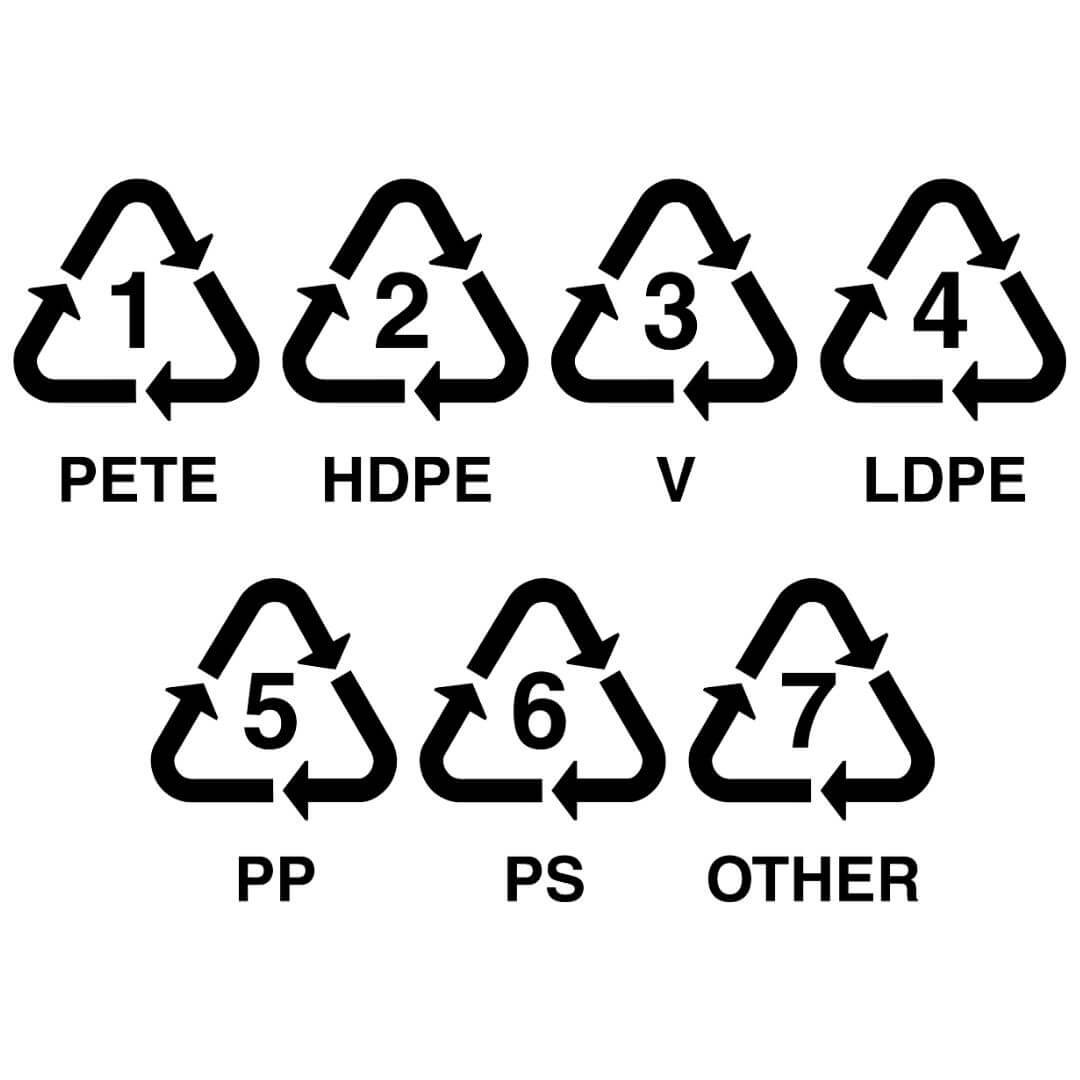

The resin identification code (RIC) is a classification system used to identify the type of plastic resin used in an item through a number encased in a triangle of arrows. This coding system, introduced in 1988 by the Society of the Plastics Industry (now the Plastics Industry Association), helps in sorting plastics for recycling purposes. The numbers, ranging from 1 to 7, correspond to specific types of plastic, such as PET (Polyethylene Terephthalate) for number 1 and HDPE (High-Density Polyethylene) for number 2. Each number aids recyclers in identifying the chemical composition of plastics more easily, optimizing the recycling process.

However these codes can sometimes be very small, and not all plastic types have a number.

Resin Identification Code

Types of Thermoplastic

-

PET - Polyethylene terephthalate

Clear Plastic Bottles, Clear Coffee Cups, Fruit Containers.

-

HDPE - High Density Polyethylene

Milk Bottles, Shampoo Bottles, Bottle Caps, Food Containers.

-

PVC - Low Density Polyethylene

Cosmetic Containers, Building Pipe, Commercial Cling Wrap.

-

LDPE - Low Density Polyethylene

Plastic Bags, Cling Wrap, Squeeze Bottles.

-

PP - Polypropylene

Food Containers, Yogurt Pots, Plastic Chairs, DVD Cases.

-

PS - Polystyrene

Food Containers, CD Cases, Party Cups, Packing Foam.

Not classifed in the standard numbering system, yet not a Thermoset, Type 7 is the code for all other types of plastics. This includes, ABS, PLA, Nylon, and much more. Most of which are still very common, fully recyclable, and often used in FDM 3D printing.

Type 7 - Other

Material Grades

-

Injection Grade

Injection grade plastics are specifically formulated for use in injection molding processes. In this method, plastic pellets are melted and injected into a mould under high pressure, where they solidify into the desired shape. This technique is highly efficient for producing complex and intricate designs with high precision. Injection grade plastics must exhibit excellent fluidity for easy moulding and solidify quickly to maintain shape integrity. Common materials used in this category include ABS (Acrylonitrile Butadiene Styrene), polycarbonate, and certain grades of polypropylene, all known for their strength, rigidity, and thermal stability

-

Blow Moulding Grade

Blow moulding grade plastics, on the other hand, are designed for the blow moulding process, where a plastic tube is heated and filled with air, expanding it into a mould. This technique is predominantly used for making hollow objects such as bottles, containers, and other similar products. These plastics need to have high ductility and the ability to stretch without losing strength to form thin, uniform walls. Materials commonly used for blow moulding include HDPE (High-Density Polyethylene), PET (Polyethylene Terephthalate), and PVC (Polyvinyl Chloride). These materials are chosen for their strength, clarity, and ability to form airtight seals.