Building the Shredder Mini - Hand Cranked Machine V1

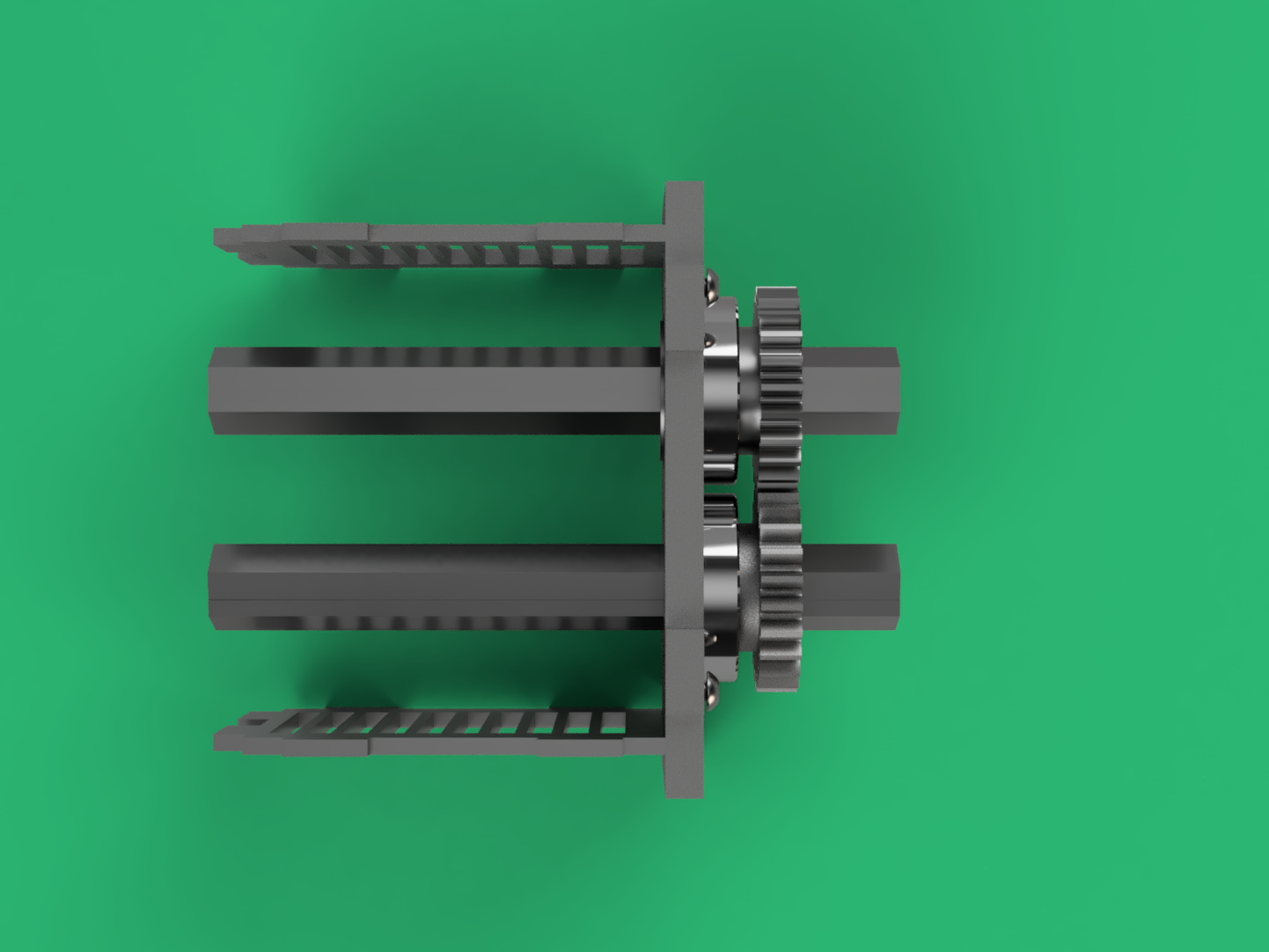

Shredder Mini Full Assembly

Required Tools

To complete this build you will need the following tools:

Hammer

Metric Allen Keys

Samll Adjustable Spanner/Wrench

High Strength Locking Fluid

Thick Grease

Frequently Asked Questions

-

For those of you who don’t know Burrs are little lines that occur on the inside and outside of the laser cuts. For most of the pieces you do not, but some may be very big and hinder your build process. If you wish to remove you can remove them with a file of sandpaper.

For any of the laser cuts that go on the two shafts. The Burrs must be aligned up with the slot on the shaft. -

You should be able to rotate the shredder shafts once built by hand with ease. If you are struggling to do this, first check your alignment. Ensuring no teeth are catching each other and secondly check that the shaft bolt is not over tightened.

Step 1

First, let us start with the two bearing plates. Place them together as shown with the one that has slightly larger cutouts in front of the other.

Step 2

Next, bolt these two plates together using the 4x M5 x 8mm Bolts.

Step 3

Now taking the 2x side plates place them as shown in the image. You may need to use a hammer to get them to fit securely in place.

Note: The vertical cutouts are slightly aligned to one side. Make sure when placing that the alignment for the plates is slightly to the right for one, and slightly to the left for the other.

Step 4

Now we need to start putting lasercuts on the shaft. There are groves on the shaft for a reason, and are to ensure the burs from the lasercuts can slide onto the shaft easily.

Basically always line the bur, or line on the lasercut with the shaft groove. For everything that goes onto the shaft from this step on.

Step 5

There are 3 sizes of Hex Spacer (Hex Hole, Round Outside). One Small, One Medium, One Large.

First we need to slide 1x Medium Hex Spacer onto the shaft as shown.

Step 6

Then we need to slide on 2x Small Hex Spacer (This has a cut out in it) onto the shaft as shown.

Step 7

Then we need to take 1x of the bearings and slide it over the Small Hex Spacer as shown.

Step 8

Next, repeat these steps, but for the second shaft and place them as shown in the slots of the lasercuts.

Step 9

Then add 2x more Medium Hex Spacers, 1x to each shaft as shown.

Step 10

Next, we need to add the 1mm Medium Hex Shims. Same size as the Medium Hex Spacers, but only 1mm thick. We need to add 2x to each shaft so that the Shim lines up with the wall of the two plates we bolted together in the first steps.

You will be able to check this by looking down from the top. A little too much is ok, but if they are recessed then you will need to add more shims.

Step 11

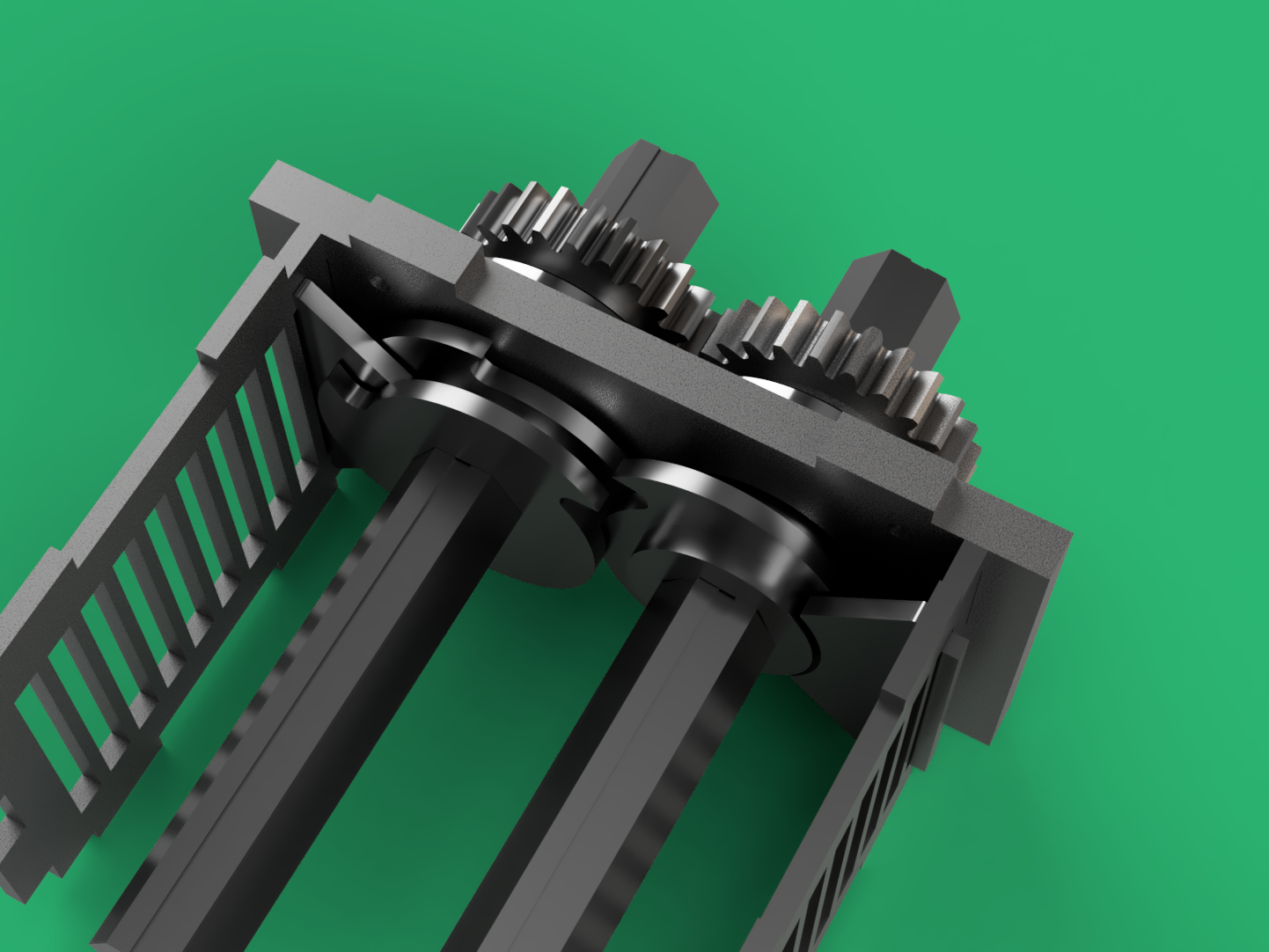

In this photo, you can see that our plates with the slots closest are on the top, and the plate with the slots further away from the bolted plates is on the bottom.

We need to add 1 more shim to the side that has the slots closest. For us, it’s the top shaft.

Step 12

From this point on we will start to create a pattern, repeating this step and the following few over and over until all the shredder teeth are placed.

First, we need to start adding the Large Hex Spacer. Let’s add 1x to the side that currently has one less Shim.

Step 13

Then finally let’s add the rotating knife to the opposite shaft as shown.

Note that the rotating knives have either 1, 2, or 3 little circles around their centre. For this first one let us use the one with 1 little circle.

Step 14

Next, we repeat those 2 steps, but on the opposite shaft, first adding a Large Hex Spacer, but this time we add the fixed tooth, and finally the rotating knife with 1 little hole marking. Make sure the teeth face each other.

Step 15

Now go ahead and continue repeating those steps anding Large Hex Spacer to one shaft, then Fixed Tooth, and then the Rotating Knife but this time with 2 holes.

Step 16

It’s important that before we get too far we check the alignment of the Fixed Teeth vs the Rotating Teeth. The Fixed Teeth want to be centred in their slots, and the Rotating Teeth want to be centred between the fixed teeth. If they are not, try adding a few of the Large Hex Shims before the first teeth to get better alignment.

Note: Spend some time getting this right. Get this wrong and it will make things very hard to shred in the future. Now go ahead and continue repeating those steps anding Large Hex Spacer to one shaft, then Fixed Tooth, and then the Rotating Knife but this time with 3 holes.

The Rotating Knives will be 2x Ver 1. One on each shaft, Then 2x Ver 2. One on each shaft. Then 2x Ver 3. One on each shaft. Then go back to Ver 1. and repeat this until the build is complete.

Step 17

Once you have gone ahead and added all the Rotating Teeth, Fixed Teeth, and Large Hex Spacers you should be left with something like this.

Step 18

Now go ahead and assemble the Second set of bearing holding plates like in Steps 1 & 2 and attach it as shown.

Step 19

Then we need to add 2 of the Medium Hex Spacers, 1x to each shaft. Then using shims add a few to each shaft so that the shims come in line with the inset laser-cut as shown.

Step 20

Then let’s add 2x Small Hex Spacers to each shaft as shown.

Step 21

Like before, we can now slide the 2x bearings over these recently added Hex Spacers. The bearings should come in contact with the lasercut plates. If they don’t you may need to remove a shim or two.

Step 22

Now we need to secure these shafts in place. To do this we will use the 2x M8 x 20mm Bolts to clamp the bearings in place. Screw these bolts with the large laser-cut washers. We don’t need these to be super tight, but they should firmly hold the shaft in place, preventing it from slipping.

Note: At this point, you should be able to turn the shafts with your hand. If they are not turning, try loosening the bolt a little. If you still have problems, your alignment may be off.

Step 23

Next you can add the top and bottom plates as shown.

Note: You should have 3 plates. 2x are identical with smaller holes. One has larger holes. This is a spacer plate so you can mount the shredder to a table.

Step 24

Finally, add the 4x M5 90mm Bolts through the bottom adding an M5 Washer. Then secure in place with another Washer and M5 Lock Nut as shown.

You now have a working Shredder Mini.

To mount, you can use the remaining holes to screw to a wooden table, with a cut out underneath or bolt it to a metal frame!

Note: To ensure longevity, once you are happy with the build, please apply locking fluid to all the nuts and bolt threads to prevent them from coming loose. We also recommend you grease the cogs with thick grease to prevent wear and tear.